When councils invest in traffic calming or public safety infrastructure, one of the most overlooked decisions is the choice of material. For decades, asphalt has been the default. It’s familiar, used everywhere, and seemingly cost-effective. But modern rubber alternatives are quickly gaining ground across Australia’s councils and private developments. They’re modular, easier to maintain, faster to install, and, in many cases, offer better long-term value.

So, which is better for council projects? Let’s break down the fundamental differences between rubber and asphalt in terms of performance, installation, maintenance, cost, longevity, and safety.

The key question for any traffic calming device is straightforward: How effectively does it do its job?

When properly laid and formed, asphalt forms a stable, permanent barrier. However, its rigidity has two drawbacks. Depending on the gradient, the surface can be uncomfortable for vehicles and elicit noise complaints from nearby homes. It is also often harsh, especially on suspension systems. Over time, the road itself experiences this wear and tear in addition to the cars.

Conversely, rubber substitutes are designed to cushion the impact of the car partially. Their adaptability successfully stops autos while minimising jarring impacts and noise. These days, many rubber systems feature surface texturing, integrated reflectors, and colour-coded areas to enhance visibility. In areas with high foot traffic and slow speeds, such as shared zones, school precincts, and shopping centre accessways, they work very well.

In wet conditions, the surface grip becomes critical. While a worn asphalt hump can become slippery, most rubber traffic calming devices are manufactured to meet high slip resistance standards. For councils that need to ensure pedestrian safety, that difference alone can justify the switch.

Asphalt installations are messy and time-consuming. They involve excavation, shaping, pouring, compacting, curing, and line marking. That’s multiple trades, multiple machines, and often several days of partial or complete lane closures. Bad weather can further delay the job, and mistakes in grading or placement are difficult and expensive to correct.

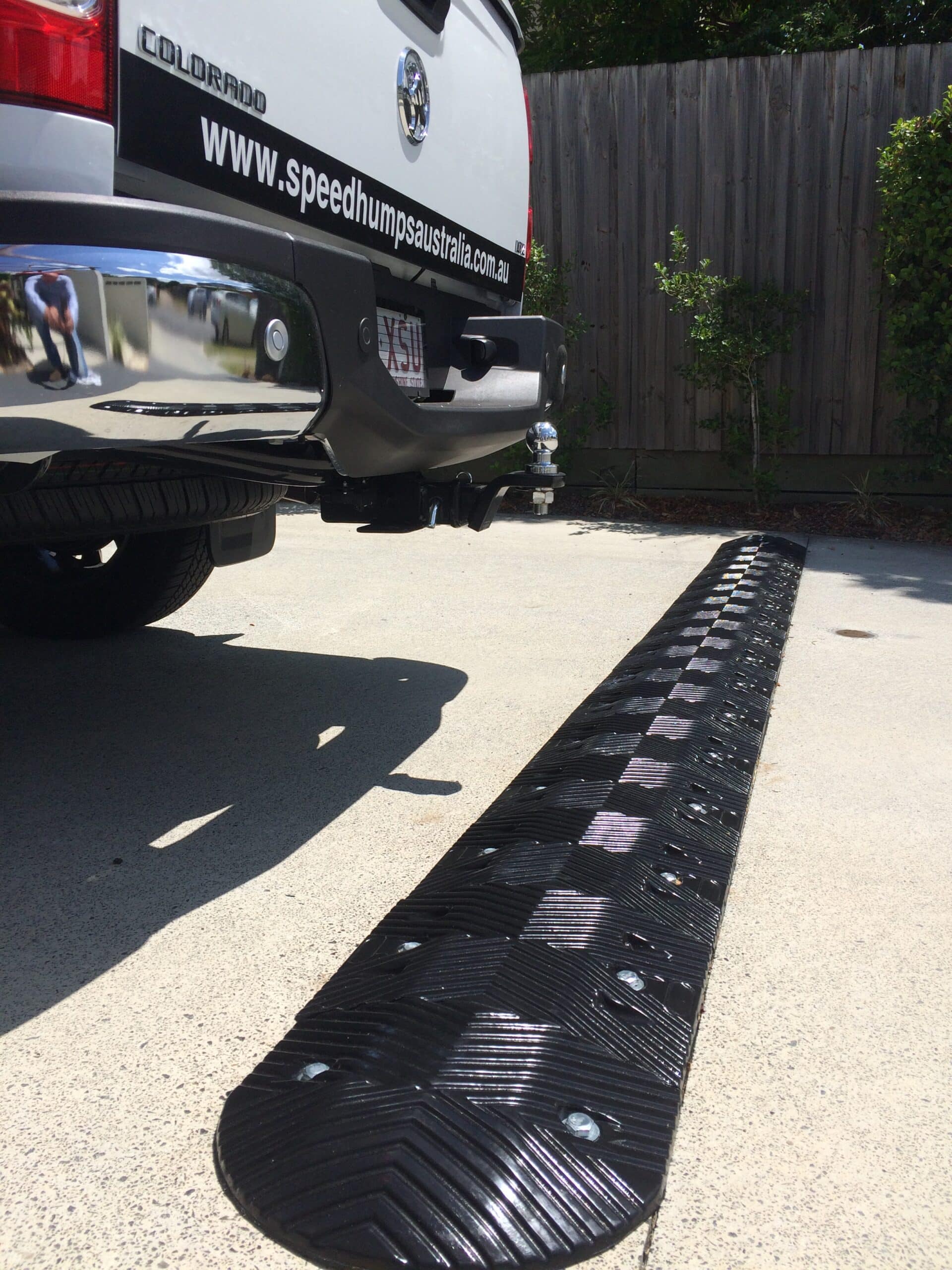

Rubber humps and rumble bars are modular and prefabricated. A crew of two can install a typical rubber speed hump in under an hour, using only basic tools. The process doesn’t require road closures and is far less dependent on weather conditions. If one section is damaged or needs to be moved, it can be unbolted and replaced on the spot, with no patching, waiting, or disruption to local traffic or emergency access.

For councils under pressure to complete work with minimal impact on residents and businesses, this installation speed is a significant advantage.

Asphalt deteriorates—heavy rain, heat waves, and constant vehicle pressure cause cracking, sinking, and surface erosion. Once cracks appear, water infiltration accelerates the damage. Repairs are costly and often leave the surface uneven. Over time, this cycle of patching and resurfacing can create maintenance issues.

Rubber solutions offer a different path. Because they’re modular, individual sections can be replaced without tearing out the entire hump. The colour-coded markings and reflectors don’t wear off as quickly, and there’s no need for repainting. In most council-grade applications, rubber speed humps and rumble bars come with multi-year warranties and compression ratings designed for trucks and high-volume traffic.

Periodic checks of the fixings are recommended; otherwise, maintenance is minimal. For cash-strapped councils managing dozens of sites, these reduced ongoing costs make rubber a more predictable investment.

Upfront Cost Versus Long-Term Value

On a pure materials basis, asphalt is cheaper per metre. That’s why it’s often still specified in standard council templates. But material cost is only part of the equation.

Asphalt installation includes equipment hire, labour, potential traffic control, and follow-up work like painting or signage. If it rains or the job takes longer than expected, those costs balloon. And once it’s in, it’s in. Any future changes mean starting over.

Rubber traffic calming devices can sometimes have a slightly higher upfront product cost, but with lower labour needs, faster installation, and no need for major equipment, these costs are offset. There are also fewer downstream costs because rubber options don’t require recoating, line marking, or resurfacing.

When councils factor in the full cost of installation, maintenance, disruption, and lifespan, the value of rubber becomes clearer. Over the past decade, rubber has consistently proven more cost-effective in shared zones, car parks, pedestrian-heavy precincts, and service lanes.

Suitability for Shared and Sensitive Zones

One of the most significant advantages of rubber traffic calming solutions is their versatility in complex environments. Asphalt is a permanent, aggressive surface modification. That can be a problem in places where comfort, safety, or adaptability are essential.

Consider these typical scenarios:

In each of these cases, rubber delivers better outcomes with less disruption and a better user experience. It’s softer under the tyre, easier to see, quicker to install, and removable if future changes require it.

That adaptability makes rubber the preferred choice in a growing number of council precincts across Australia.

Councils now face mounting pressure to choose sustainable infrastructure solutions. Asphalt is made from petroleum-based products, requires high temperatures to produce, and often ends up cracked and discarded into landfills.

By contrast, many modern rubber traffic devices are made from recycled materials, including old tyres and plastics. They’re manufactured at lower energy levels, shipped in modular form, and create virtually no waste during installation. And because they last longer and are easily repairable, fewer materials are needed over the product’s lifespan.

For councils working toward environmental targets, rubber presents a responsible alternative with measurable outcomes.

If your project involves significant road resurfacing or a permanent change to a thoroughfare, asphalt still has a role. It blends seamlessly with roadways and can be shaped to suit various conditions. However, in nearly every other council context—such as school zones, residential accessways, shopping centres, car parks, or mixed-use lanes—rubber is the better solution.

It installs faster, performs better, creates less noise, requires less maintenance, and delivers more value over time. As the market continues to shift toward modular, council-grade infrastructure, rubber traffic calming solutions are becoming the new standard, not an alternative.

Want a more innovative solution for your next council project?

At Speed Humps Australia, we supply rubber speed humps, rumble bars, and modular traffic control products. We’ve helped councils, schools, retail centres, and contractors across the country deliver safer roads with less disruption.

Discuss your site conditions with our team, and we’ll help you find the best fit.

For 10 years, our focus has been on one thing: to provide one style of product and to do it well.

Our wheel stops, speed humps and rumble bars meet Australian Standards, don’t fade, and we’ve never needed to replace one.

For 10 years, our focus has been on one thing: to provide one style of product and to do it well.

Our wheel stops, speed humps and rumble bars meet Australian Standards, don’t fade, and we’ve never needed to replace one.